Basic Info.

Fine Blanking

Open

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.01mm

Customized

Customized

Transport Package

Carton, Wooden Case or as Required

Specification

Customized

Trademark

Customized

Origin

China

HS Code

7326191000

Production Capacity

100000PCS/Year

Product Description

| Product description | |

| Item name | Customized Galvanized Steel Bending and Stamping Sheet Metal Part Household Electrical Appliance |

| Design | We use the most advanced die design software Auto CAD, Pro/E, Solidworks, |

| UG (dwg, dxf, IGS, STP, X-T) | |

| Processing Type | Multistep Progressive Dies |

| Tolerance | as per customers' requirement. |

| Material | Carbon Steel, Aluminum, Brass, Stainless steel etc. |

| Process | Laser cutting, stamping, machining, bending, deep drawing, welding, riveting, |

| plating, polishing, brushing, painting, powder coating, assembly etc | |

| Surface Treatment | Cleaning, Anodizing, Plating, Galvanize, Tempered, heat treatment, |

| electrophoresis, Paint, Powder Coating, Polishing, Brushing, Silkscreen etc. | |

| Type | Cold stamping |

| Industry Of Use | Automobile, Manufacturing Machinery, Electronics, Industrial Equipment, |

| Electrical, Construction&Decoration, Lighting, Transportation, Medical, | |

| Sample Lead-time | Within 1 day for samples available from our stock About 1-2weeks |

| for custom samples | |

| Mass Production Lead-time | 2-5 weeks after receiving deposit |

| Payment Terms | EXW/FOB Tianjin or any other airport or seaport, China |

| Payment | 30% deposit, balance against B/L copy |

| Delivery Time | 2-4 weeks according to production process and order qty. |

| Package | Carton,Wooden Case or as Required |

| Service Type | OEM&ODM |

| Inspection | In-house or third party, all the products are strictly inspected by skilled QC |

| Certification | ISO9001,SGS Certification. |

| Main customers | Nokia,ABB,AEG, |

| MOQ | Flexible, according to customer's requirement |

| Convenient Location | 3hrs' driving to Beijing Airport, 2.5 hrs' driving to Tianjin seaport. |

Cangzhou Yifeng Hardware Manufacturing Co., Ltd specialize in this field for more than 20 years, covering:

1.High precision stamping parts,

2.Sheet metal parts,

3.Copper bars,

4. Electronic components,

5.Chassis cabinets 6.Other metal products as well as injection molding products.

Technical process advantages: the whole process of manufacturing: stamping - sheet metal - welding - surface treatment - assembly - inspection and testing.

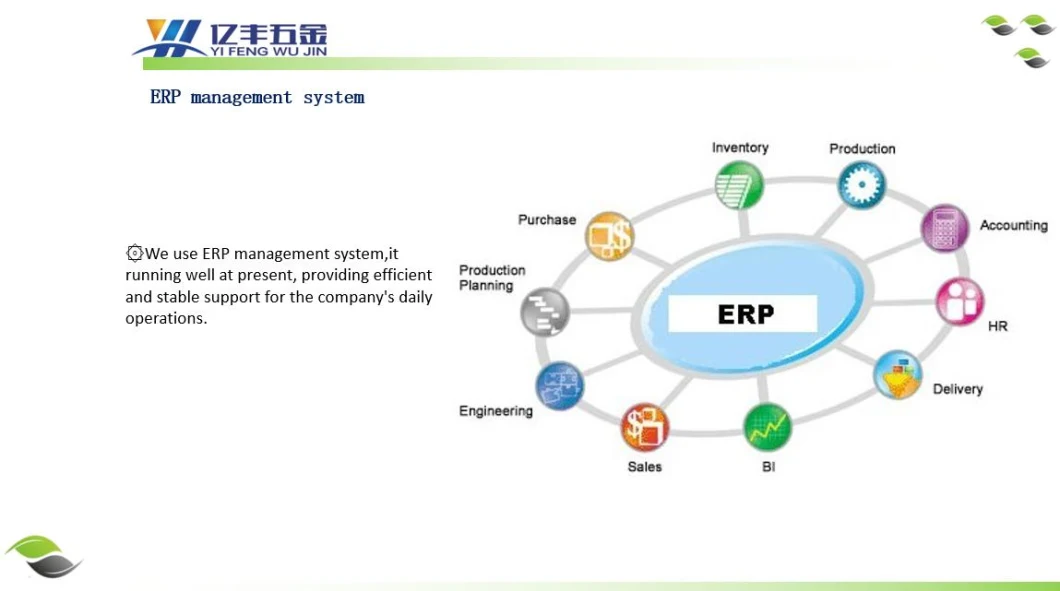

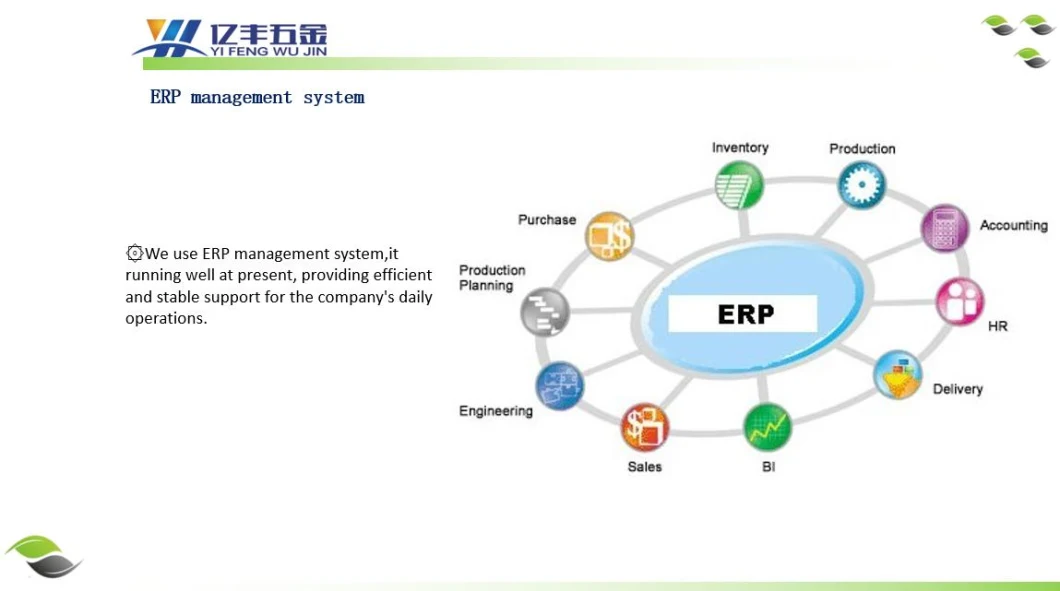

ERP management system: We have achieved full coverage of resource management, including: human resources, equipment and safety, supply chain, production flow, technical processes, quality control and other fields.

ERP management system: We have achieved full coverage of resource management, including: human resources, equipment and safety, supply chain, production flow, technical processes, quality control and other fields.

Powder painting

Powder painting

Warehouse

Warehouse

Shipping

Design software Auto CAD, Pro/E, Solidworks,

Technical process advantages: the whole process of manufacturing: stamping - sheet metal - welding - surface treatment - assembly - inspection and testing.

ERP management system: We have achieved full coverage of resource management, including: human resources, equipment and safety, supply chain, production flow, technical processes, quality control and other fields.

ERP management system: We have achieved full coverage of resource management, including: human resources, equipment and safety, supply chain, production flow, technical processes, quality control and other fields.

Warehouse

Warehouse

Shipping